Home

ꄲ

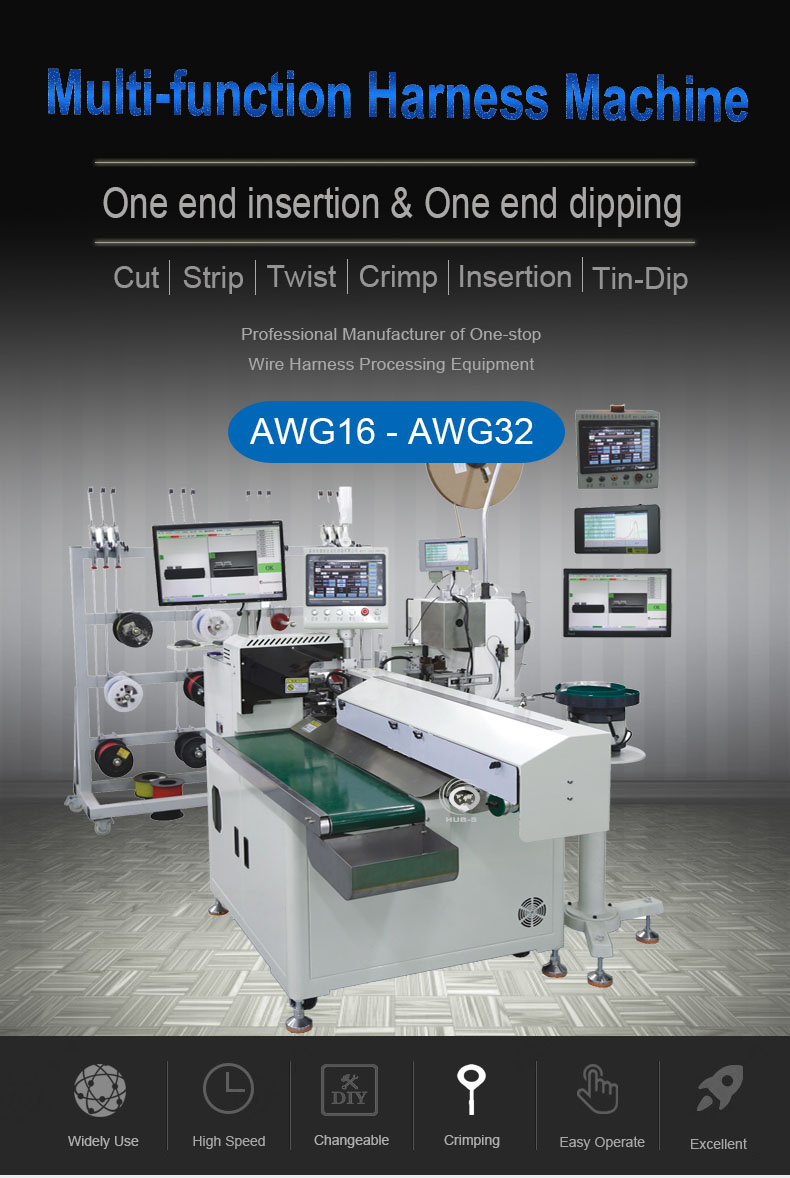

Multi-function wire harness machine

ꄲ

Fully Automatic Wiring Harness Process Machine One End Tin DIP Another End House Insertion

Fully Automatic Wiring Harness Process Machine One End Tin DIP Another End House Insertion

1. This full automatic machine is mainly used for wire cutting,both end stripping and crimping, wire reverse processing, and both end terminal connector inserting.

2.Single head with house assemble inserting and double ends with terminal crimping.

3.It's good choice for electrical cable wire processing and manufacturing industries like automation area, automobile area, aerospace/aviation area, appliance industries etc.

2.Single head with house assemble inserting and double ends with terminal crimping.

3.It's good choice for electrical cable wire processing and manufacturing industries like automation area, automobile area, aerospace/aviation area, appliance industries etc.

| Model | YG-09 |

| Function | Wire cut, strip, and twist, single end terminal crimping and housing insertion, one end tin dipping |

| Detection Function | wire alarm, wire knot alarm, wire shortage alert, stripping detection, gas pressure alarm, Shell bad detection and screening. Pressure management device (optional) , visual inspection device |

| Capacity | 5500-6000 pcs/h |

| Processing Range | ZH1.5, PH2.0, XH2.54, SM male and female (shell range 1.0, 1.25, ZH1.5, PH2.0, XH2.54,2510, SM female and male, VH3.96, Plastic shell 2pin -12 Pin |

| Processing length | 25mm-800mm(special manufacturers can consult) |

| Wire range | AWG16-AWG32(depending on wire) |

| Machining accuracy | 0.2+0.2%L(depending on wire) |

| Stripping length | A end 1-5mm, B end 1-5mm(special customized) |

| Stripping accuracy | ±0.2(depending on wire) |

| power supply | 220V/60HZ |

| Maximum power | 1500W |

| Air source | 0.5-0.7mpa (clean and dry air source is required) |

| Dimension | L1150xW985xH1500(excluding cable tray and conveyor belt) |

| Weight | About 680KG(excluding cable rack and conveyor belt) |