Home

ꄲ

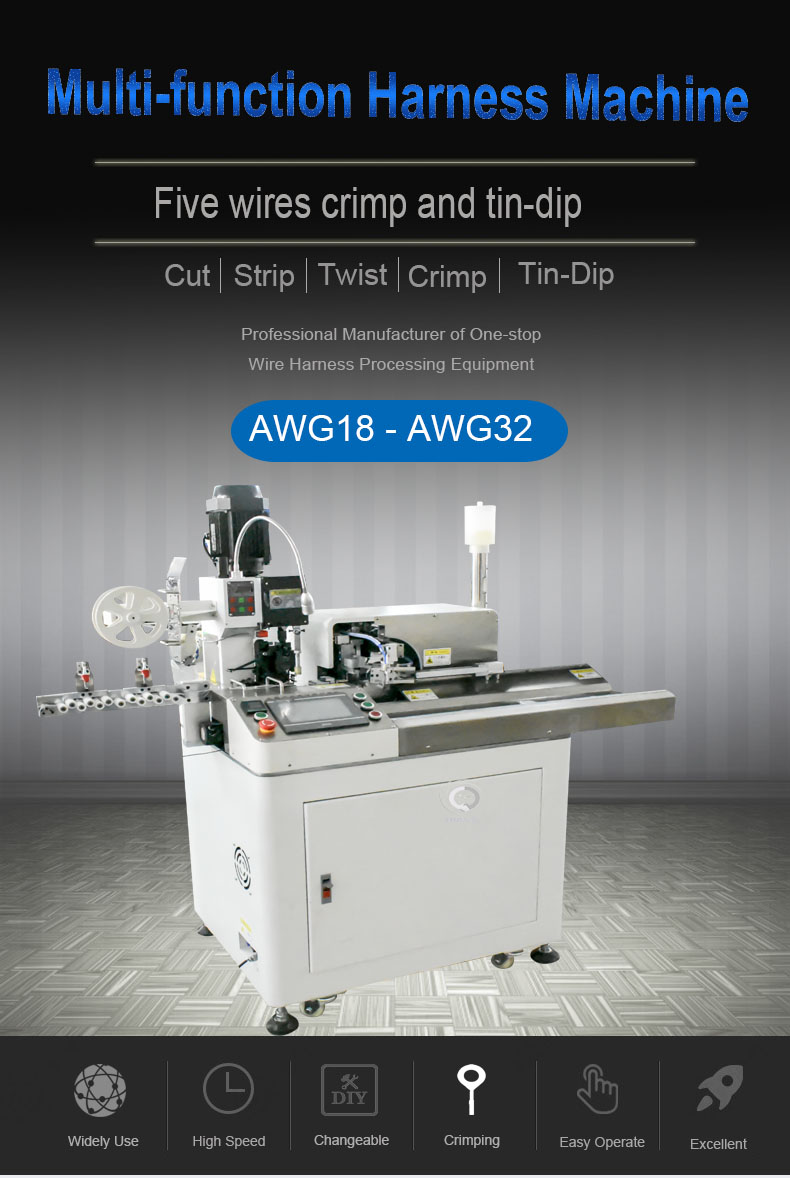

Multi-function wire harness machine

ꄲ

Fully Automatic Five Wires Single Head End Tin Dipping and Crimp Machine

Fully Automatic Five Wires Single Head End Tin Dipping and Crimp Machine

1. This full automatic machine is mainly used for wire cutting,both end stripping and crimping, wire reverse processing, and both end terminal connector inserting.

2.Single head with house assemble inserting and double ends with terminal crimping.

3.It's good choice for electrical cable wire processing and manufacturing industries like automation area, automobile area, aerospace/aviation area, appliance industries etc.

2.Single head with house assemble inserting and double ends with terminal crimping.

3.It's good choice for electrical cable wire processing and manufacturing industries like automation area, automobile area, aerospace/aviation area, appliance industries etc.

| Model | YH-05ss |

| Function | Five Wires cut, strip, single end terminal crimping and one end tin dipping machine |

| Detection function | Wire end detection, missing wire detection, wire knotting, air pressure detection |

| Capacity | 6500 - 800 pcs/h or more per hour |

| Processing Range | ZH1.5, PH2.0, XH2.54, SM male and female (shell range 1.0, 1.25, ZH1.5, PH2.0, XH2.54, SM male and female) Insert shell structure according to different shell can be easily replaced (special specifications can consult manufacturers) |

| Crimping ability | 2.0 Tons |

| Wire range | AWG32-AWG18(depending on wire) |

| Dip length | 1- 10 mm |

| Stripping length | 0.1- 10 mm |

| Twisted wire length | 2-10 mm |

| power supply | 220V/60HZ |

| Maximum power | 1200W |

| Air source | More than 6KG |

| Dimension | L1210*770*1370 mm (excluding cable tray and conveyor belt) |

| Weight | About 450KG(excluding cable rack and conveyor belt) |