Home

ꄲ

Multi-function wire harness machine

ꄲ

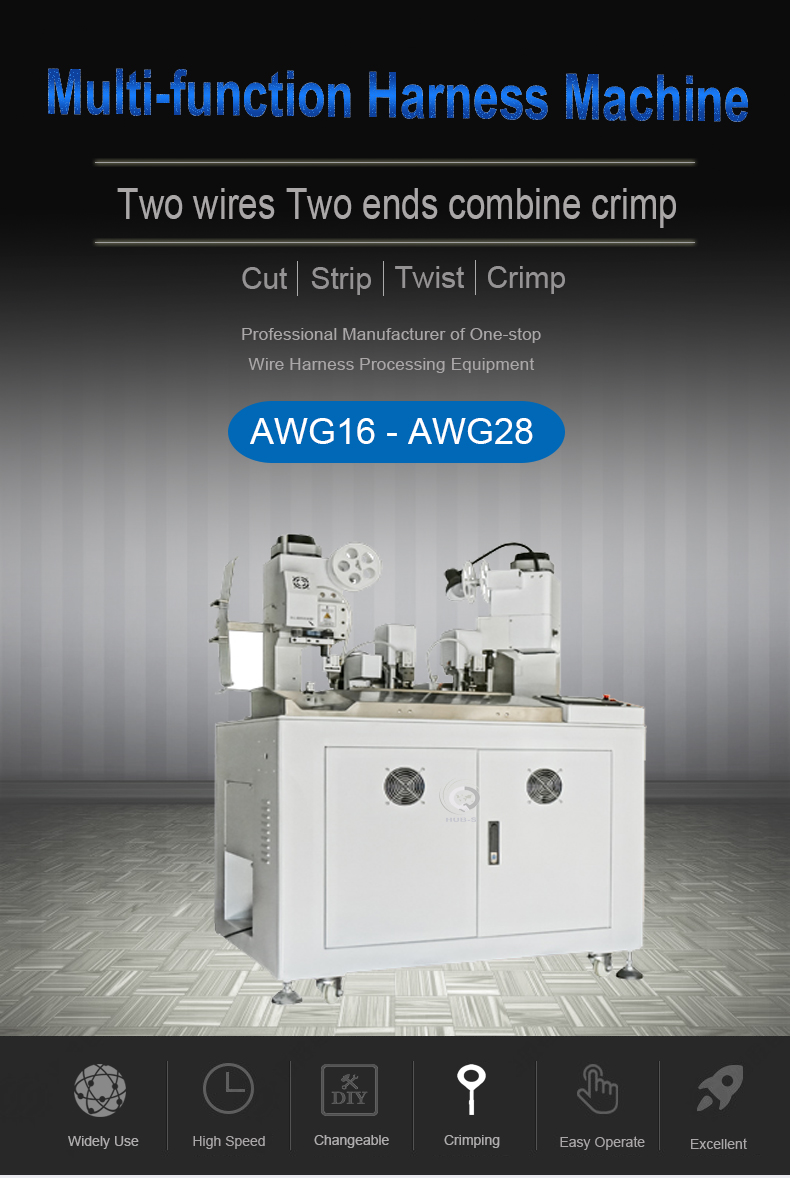

Fully Automatic Double Wire Two Ends Crimping Machine (Combined crimp)

Fully Automatic Double Wire Two Ends Crimping Machine (Combined crimp)

* Wide versatility: mainly used for pressing: PH,XHEH, ZH et rehearsals harness terminal. SUV, SM, VH, DuPont strip for a connector cable terminal:

* High precision: Panasonic servo motor,Panasonic PLC and HMI as the core control system so that the machine runs coherence, greater stability,an accuracy of 0.1mm,the stepper motor is more than quality assurance;

* High precision: Panasonic servo motor,Panasonic PLC and HMI as the core control system so that the machine runs coherence, greater stability,an accuracy of 0.1mm,the stepper motor is more than quality assurance;

| Model | WH-014 |

| Function | Wires cut, strip, Three end terminal crimping |

| Detection device | Whetaher there is a terminal and wire, crimp inspection, air pressure detection, wire knot detection |

| Capacity | 3500 pcs/hour |

| Processing Range | AWG#16-AWG#28 |

| Maxi PIN number | 20P |

| Display method | Color LCD touch screen |

| Stripping length | 0.5-15mm |

| power supply | 220V/60HZ |

| Cutting length | 50-1500 mm |

| Air source | 0.4-0.6 mpa |

| Dimension | 1000*800*1650 mm (excluding cable tray and conveyor belt) |

| Weight | About 400KG(excluding cable rack and conveyor belt) |