Home

ꄲ

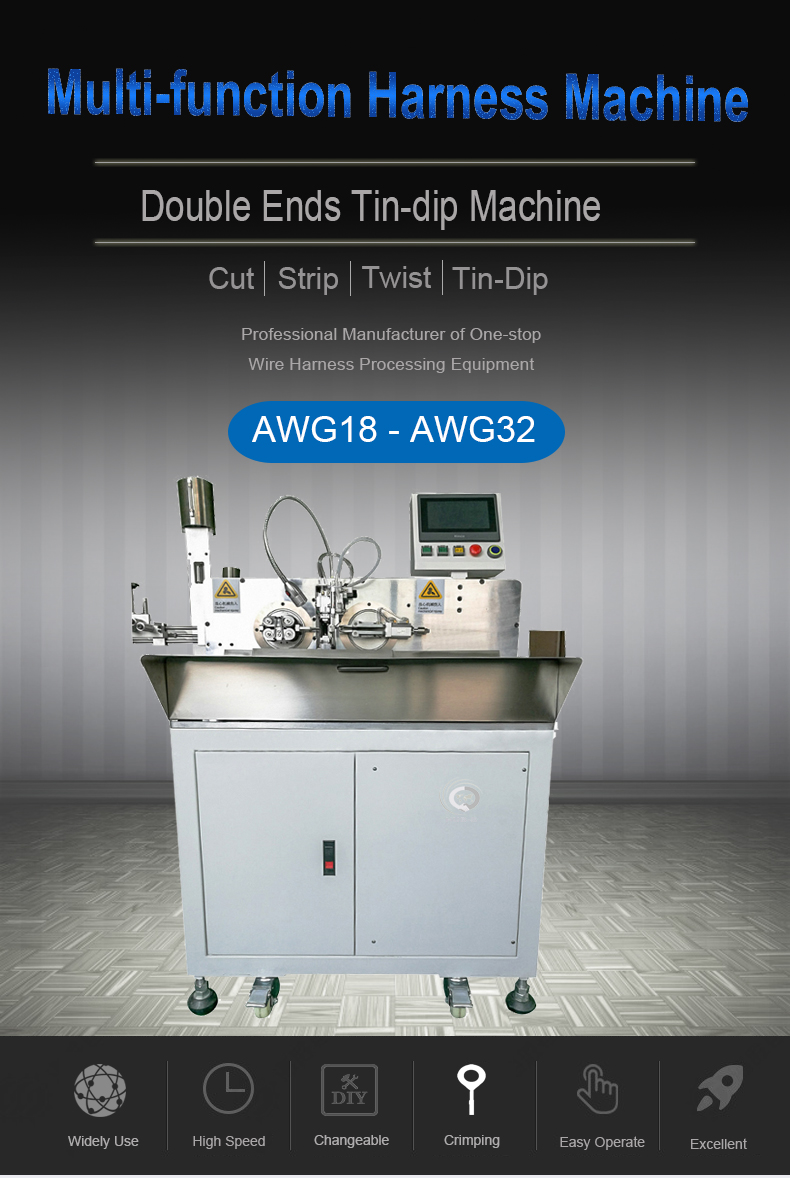

Multi-function wire harness machine

ꄲ

Fully Automatic Wire Double Ends Strip Twist and Tin DIP Machine

Fully Automatic Wire Double Ends Strip Twist and Tin DIP Machine

* Compact and compact design, excellent concept and small footprint.

* Modular design, the adjustment of the machie has a great advantage compared with the traditional mechanical type, computer touch screen Chinese and English operation system. Cutting length, stripping length, twisting length and dip tin length parameters can be adjusted on the screen. Easy to use , the replacement process and materials quickly save time and effort.

* Modular design, the adjustment of the machie has a great advantage compared with the traditional mechanical type, computer touch screen Chinese and English operation system. Cutting length, stripping length, twisting length and dip tin length parameters can be adjusted on the screen. Easy to use , the replacement process and materials quickly save time and effort.

| Model | DT-01 |

| Function | Wires cut, strip, twist and double ends tin dipping |

| Processing method | Roller wire feeding |

| Capacity | 16000-22000 pcs/h or more |

| Processing Range | AWG#18 - AWG#32 (0.15 -3.5 MM) |

| Cutting length | 8-9999mm |

| Stripping length | 0.1-10mm |

| Twist length | 3-10mm |

| power supply | 220V/60HZ |

| Dip length | 21-10mm |

| Air source | 0.4-0.6 mpa |

| Dimension | 840*670*1200 mm (excluding cable tray and conveyor belt) |

| Weight | About 310 KG(excluding cable rack and conveyor belt) |